Our capabilities

Our Unique Capabilities for Excellent Advancements

Aluminium Die Casting

Microturner Group’s Aluminum Die Casting Division, founded in 2018, leverages Industry 4.0 technology for the future of metalworking which ensures consistent quality and efficiency by overseeing robotic furnaces. We offer a variety of casting methods (gravity, low pressure, high pressure) and diverse finishing options (powder coating, painting, heat treatment). For a complete solution, Microturner Group provides one-stop-shop convenience with comprehensive in-house machining capabilities featuring BTA processes.

Press and Fabrication

Microturner Group expands with a new Press & Fabrication Division, delivering top-quality sheet metal and tubular assemblies for your two-wheeler needs. Our cutting-edge welding setups and automated systems guarantee efficiency and exceptional product quality. We’ll be manufacturing swing arm assemblies and main stands using our own innovative designs.

Seamless tubes

MT Group has expanded into the seamless tube market with a cutting-edge facility located in Himachal Pradesh, India. This new venture boasts an initial production capacity of 36,000 Metric Tons annually. Our cold-finished tubes are manufactured to meet the most rigorous quality standards, serving a wide range of applications across industries like automotive and mining. Committed to future growth, we already have plans in place to expand our capacity to 110,000 Metric Tons.

Forging and Machining

From concept to completion, we offer comprehensive metal shaping solutions. Our capabilities include hot and cold forging for components like gears, shafts, axles, and fasteners. Precision machining takes shape through CNC turning, grinding, broaching, gear hobbing, and various surface finishing techniques.

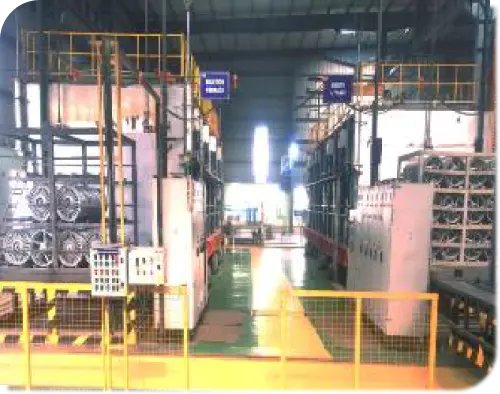

Surface Treatment

Our state-of-the-art surface treatment facility offers a wide range of options to elevate and safeguard your products. We specialize in zinc plating (available in white, silver, yellow, and black finishes), zinc iron plating, zinc nickel plating, copper plating, zinc phosphating, nickel hard chrome plating, powder coating (both PP and epoxy options), and liquid painting. These treatments are ideal for various components, including axles, fasteners, studs, brake cams, under brackets, alloy wheels, and bottom cases.

Heat Treatment

Our heat treatment capabilities encompass a wide range of processes, including carbonitriding, carburizing, hardening, tempering, normalizing, annealing, nitriding (liquid and gas), coil annealing, isothermal annealing, and induction hardening. This ensures we can deliver the precise material properties your project demands.

Industrial Mart

Micro Industrial Mart has been a trusted partner for industrial supplies since 2014. We offer a diverse selection of high-quality products at globally competitive prices. Our vision is to empower your business with sustainable and cost-effective solutions across various industries.

Green Energy

Demonstrating our commitment to a greener future, MT Group proudly operates a 9 MW solar power plant spanning 50 acres in Ambala since 2017. This significant investment in renewable energy helps us reduce our environmental impact and contributes to a more sustainable future for generations to come.

axle and fasteners

Micro Turners Group Expands with a new Axle & Bolt facility in 1990, special Fasteners facility in 1995. we have facility of part former, Bolt maker, Nut Former and Headers having different ranges of Min.-Ø10×190 & Max. Ø17×350. We specialize in zinc plating (available in white, silver, yellow, and black finishes), zinc iron plating, zinc nickel plating, copper plating, zinc phosphating, nickel hard chrome plating. We have also facility available for Geomet Plating.

Our OEM Partners

Our patrons who stand by our quality and trust on our expertise

30+

5500+

Since 1969